- Home

- Acoustic Materials

- Project

- Information

- Service

- About Master Acoustic

- Contact Us

-

The polyester acoustic panel is made of polyester fiber, and it is cocoon-like cotton after hot pressing. The porosity can reach more than 90%, and it has good sound absorption performance in the middle and high-frequency range.100% recyclable material.

V grooved acoustic panel has the characteristics of high density, non-combustion, wide sound-absorbing frequency band, decoration, simple construction, easy cutting, and no dust pollution. The performance of the high-quality version can reach Level B of flame retardant and Level E of environmental protection.

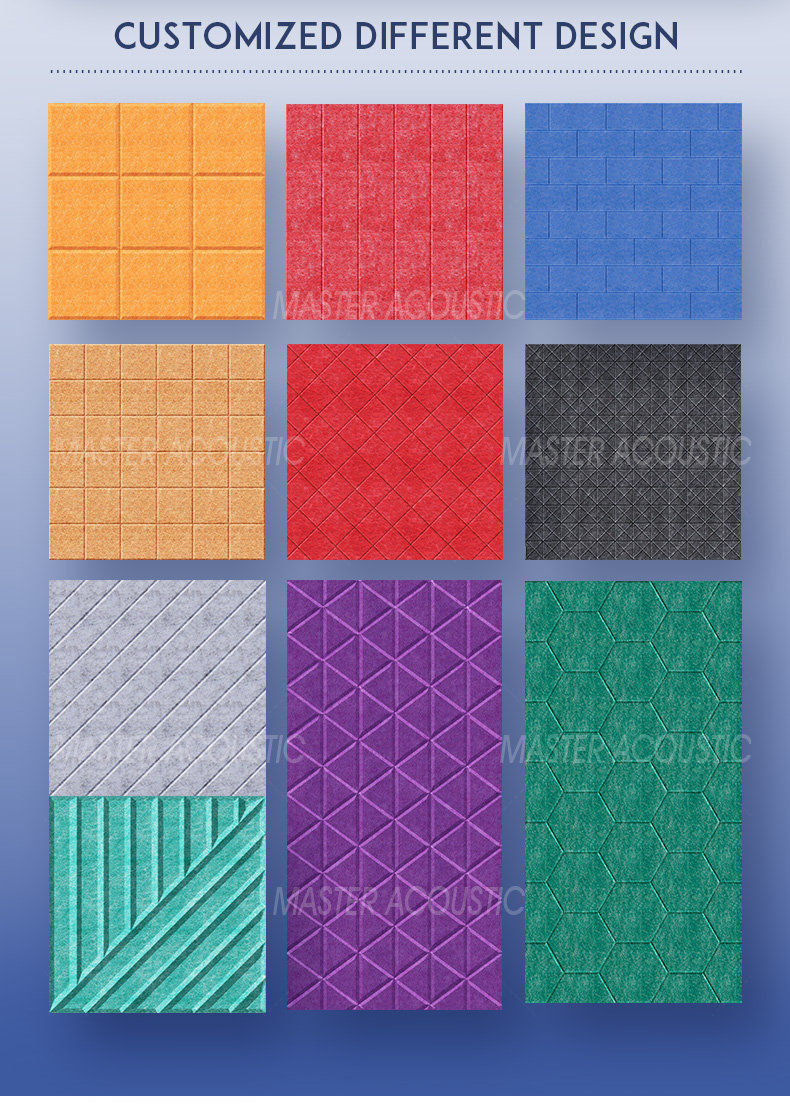

Hundreds of colors are available. The color of the V-grooved acoustic panels is fashionable and gorgeous. You can cut various shapes at will, which can meet the customers' diversified acoustic and decoration needs.

INQUIRYThe sound absorption characteristics of PET acoustic panels are similar to those of other porous materials. The sound absorption coefficient increases with the increase in frequency. The high-frequency sound absorption coefficient is very large. The cavity on the back and the spatial sound-absorbing body formed by it can greatly improve the material's performance. Sound absorption performance.

The noise reduction coefficient of the Polyester Fiber Acoustic Panel is about 0.8-1.10, which becomes a wide-band high-efficiency sound-absorbing body. At the same time, it has the advantages of non-combustibility, anti-collision, decoration, no dust pollution, and simple construction.

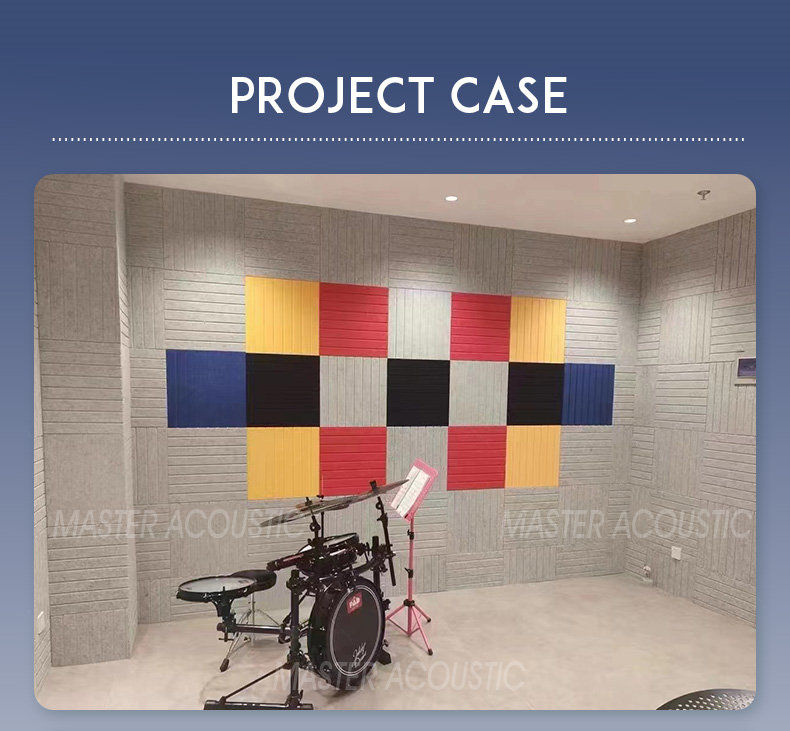

A V-grooved acoustic panel is typically used in environments where sound quality and noise control are important, such as recording studios, home theaters, conference rooms, and commercial spaces.

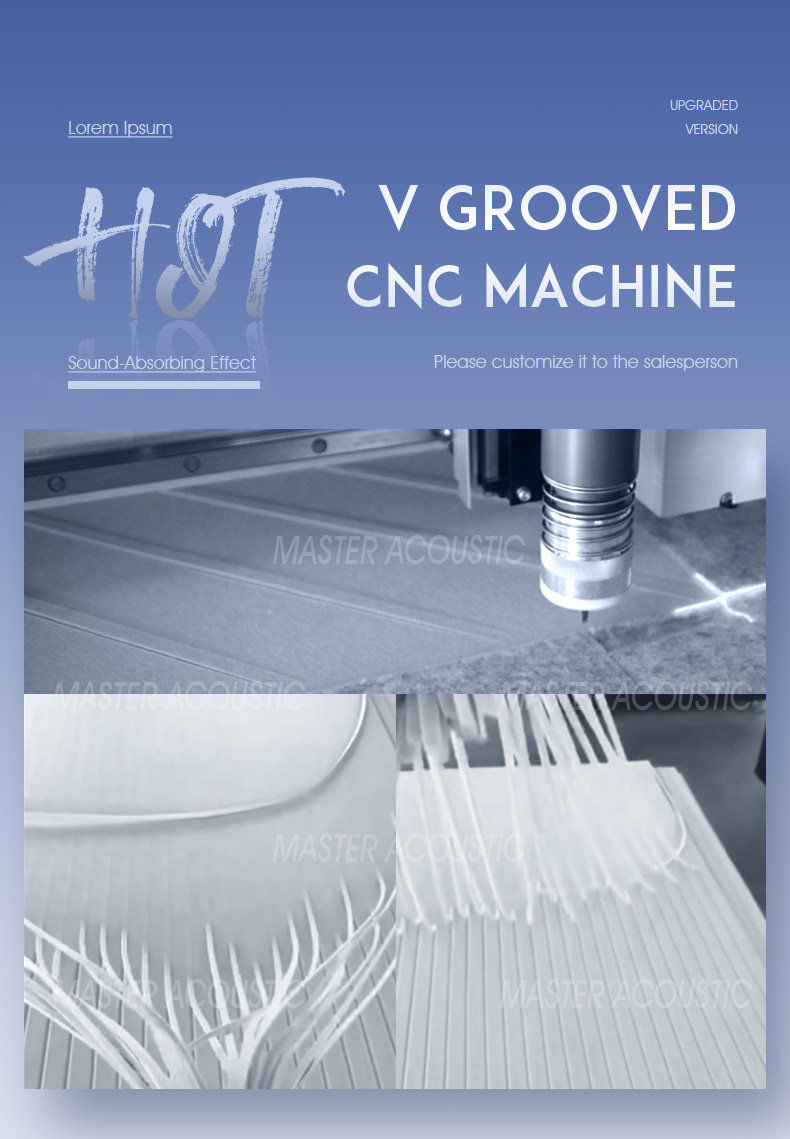

Design: V-grooved panels have a distinctive appearance with grooves or channels cut into the surface of the panel. The grooves create a textured surface that not only enhances the aesthetics but also contributes to the panel's acoustic performance.

Sound Absorption: The grooves in the panel help trap and dissipate sound waves, preventing them from bouncing off walls and causing echo or reverberation.

Customization: V-grooved acoustic panels can be customized in terms of size, shape, groove pattern, and color, allowing for flexibility in design and integration with the room's aesthetics.

Installation: These panels are usually mounted on walls or ceilings using various methods, including adhesive, clips, or suspension systems. Proper installation is crucial to ensure they perform optimally.

Sound Control: V-grooved panels help control sound by reducing echoes, improving speech intelligibility, and creating a more comfortable acoustic environment. They are often used in conjunction with other acoustic treatments, such as bass traps and diffusers, for comprehensive sound control.

Aesthetics: In addition to their acoustic benefits, V-grooved panels can enhance the visual appeal of a space. They can be finished with various fabric coverings or wood veneers to complement the room's decor.

When considering V-grooved acoustic panels for a project, it's recommended to consult with Master Acoustic to determine the appropriate panel type, quantity, and placement for your specific acoustic needs.

_4151.jpg)

_4152.jpg)

_4153.jpg)

_4154.jpg)

_4155.jpg)

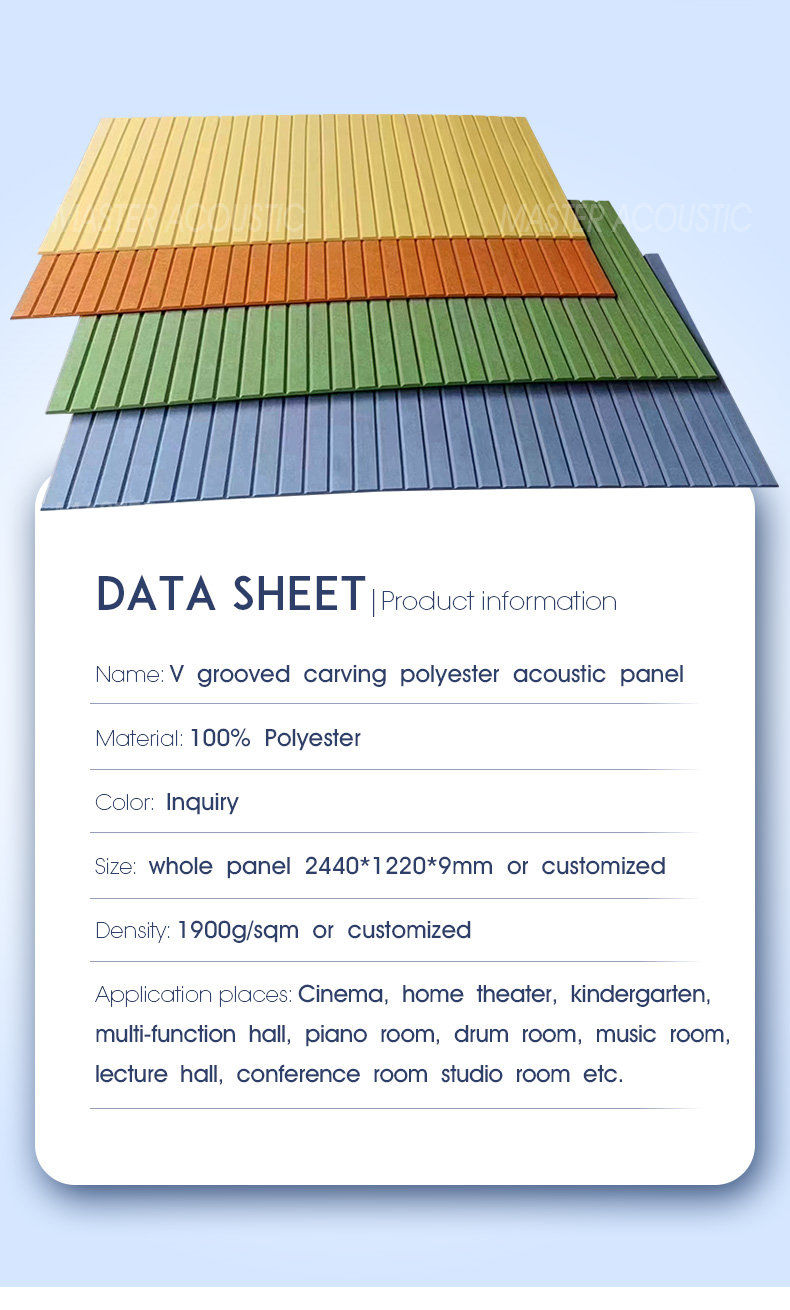

Product parameters

Material: 100% polyester fiber

Size:2440*1220/customized

Thickness:9/12/24mm/customized

Density: 160-229kg/㎡/customized

Color: hundreds of colors (please contact customer service)

Environmental protection grade: E1

Fire retardant : EN 13501 B-s1, d0,

V grooved size: Customized

_4150.png)

A. decoration

PET Fiber Acoustic Panels come in dozens of colors and can be assembled into various patterns. The surface shape is flat, square (mosaic Shape), wide strips, thin strips, and the plate can be bent into a curved shape. It can make the interior wall design more flexible changeable and effective. Even geometric perforation and cutting technology can be printed on PET acoustic panels through the computer.

B. Acoustic function

100% Polyester fiber is hot-pressed with high technology and made in the shape of cocoon cotton to achieve density diversity to ensure ventilation and become a high-quality product in sound absorption and heat insulation materials. The highest sound absorption coefficient is above 0.9 in the noise range of 125~4000Hz. , The sound absorption coefficient increases with the increase of the frequency. According to different needs, the reverberation time can be shortened to clear the sound impurities, improve the effect of the influence, and improve the clarity of speech. Become a broadband high-efficiency sound-absorbing panel.

C. Applicable place

Fiber Polyester Acoustic Boards are currently widely used in movie theaters, interrogation rooms, public security bureaus, piano rooms, drum rooms, recording studios, broadcasting rooms, TV stations, business offices, multi-function halls, conference rooms, studios, auditoriums, stadiums, and entertainment Places, KTV boxes and other places with higher acoustic requirements, and at the same time, the current family villas have also begun to be widely used, especially the basement ceiling and indoor walls.

D. Installation method

During construction, it is necessary to cut the surface of the PET Wall Acoustic Panels. It is recommended to use a steel ruler or alloy square steel as a ruler when cutting. Do not use wooden strips or soft materials as a ruler to prevent the cutting line from being straight and causing splicing gaps. Too large or distorted. In order to reduce the splicing gap, the blade can be tilted inward by 0.5-1mm during cutting, so that the interface surface forms an inner bevel, which makes it easy for the board to be connected during construction and reduces the gap.

1. Are you a trading company or a factory?

Our company was established in Guangzhou city, with the factory in Foshan. We are a manufacturer engaged in acoustic products for more than 10 years. Welcome to visit our factory.

2. How can you guarantee the quality?

We are strict on every step of production to ensure the best quality. We provide a full-scale quality management system and pass the ISO9001 quality assurance system.

3. Can you offer a sample?

Yes, we can offer standard samples for free, and customization is available.

4. Do you accept customization?

Yes, we can support our clients with OEM, so that it can be easier to open the local market and build a long-term partnership between us.

5. How long is the lead time?

Normally 10-25 days upon receiving the deposit, based on the quantity of 1,500 SQM

6. Can you assist with installation?

Yes, we can arrange to assist in installation if needed.

7. Do you have a CE certificate?

Yes, we have. We have shipped many goods to European countries.

8. What are the factors influencing the NRC?

Perforation rate, the gap between the wall and panel, the density and thickness of the glass wool, etc. All these factors will effect NRC.

9. How about the capacity of your factory?

We can produce 500,000 sqm of acoustic materials per year.

10. How to pay?

You can pay by Western Union or T/T. Cash will be okay if we do business face-to-face.

More questions or details about our products or company, please feel free to contact us.