- Home

- Acoustic Materials

- Project

- Information

- Service

- About Master Acoustic

- Contact Us

-

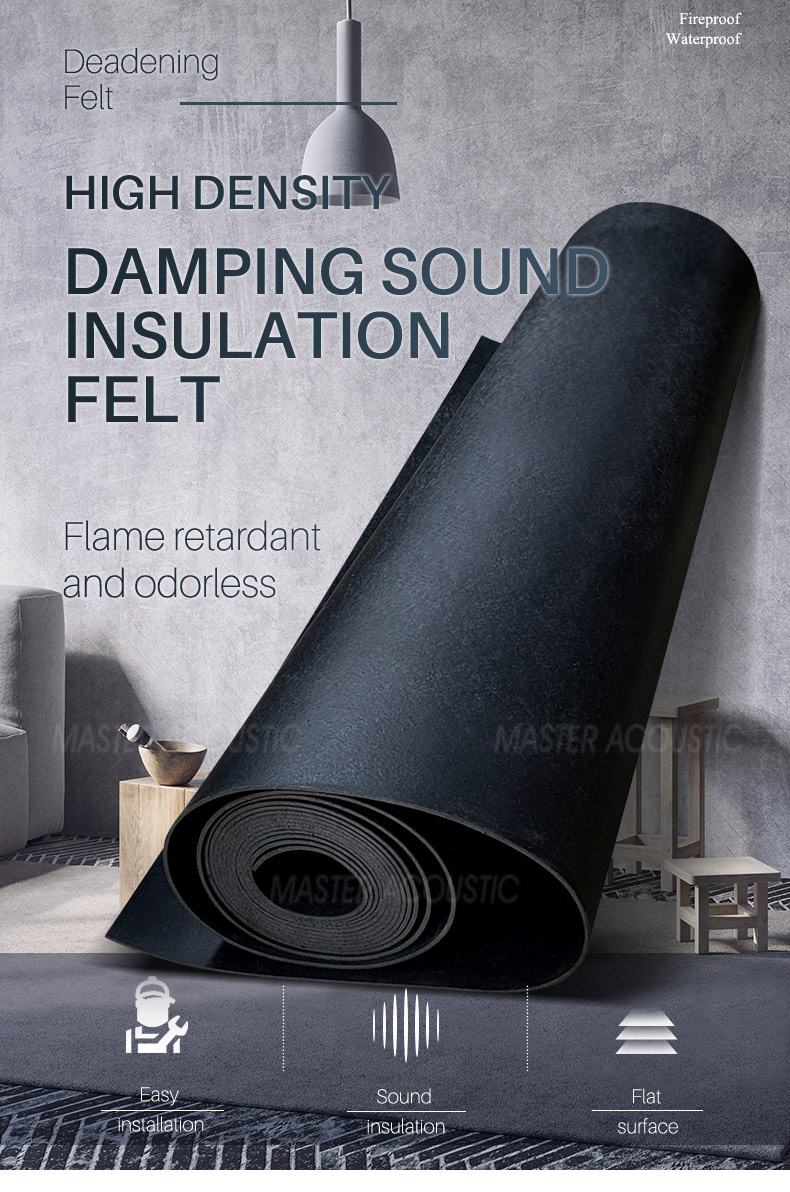

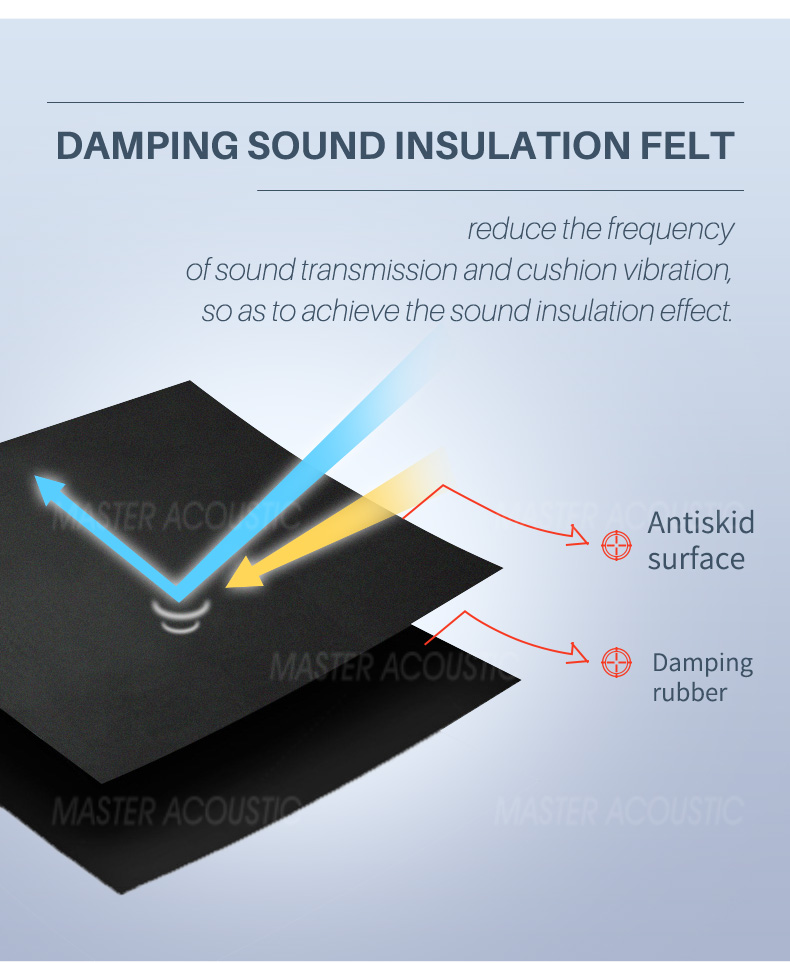

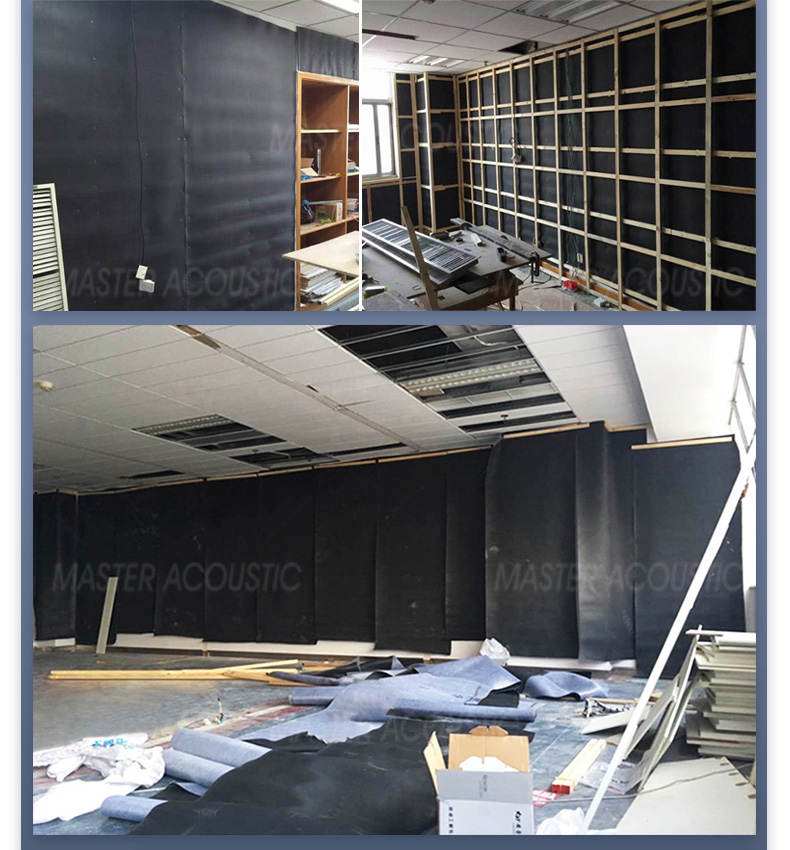

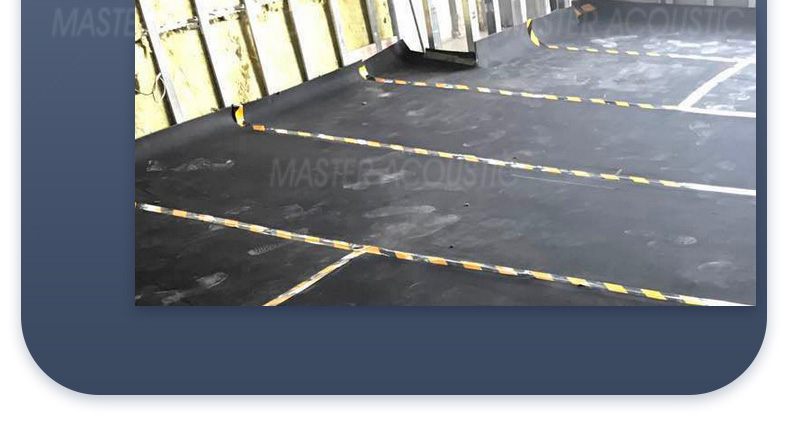

The damping sound insulation felts MLV are made of polymer-metal powder, various auxiliary agents, and PVC, and then pressed. It is a new type of building sound insulation material that controls the sound attenuation of noise in the transmission path.

INQUIRYMLV is used for sound insulation and damping in various applications. MLV is a dense, flexible, and heavy vinyl sheet that helps block the transmission of sound waves and makes it effective for soundproofing.

● Sound Barrier

It's commonly used to reduce noise transmission through walls, ceilings, and floors.

● Flexibility

MLV is flexible and can be easily cut or shaped to fit different spaces and configurations, making it versatile for various soundproofing projects.

● Mass

The density and mass of MLV are crucial for its effectiveness. The added mass helps absorb and block sound energy, reducing noise levels significantly.

● Easy Installation

MLV is typically installed by attaching it to existing surfaces using adhesive, screws, or other mounting methods. It can also be sandwiched between layers of drywall or other building materials.

● Versatile Applications

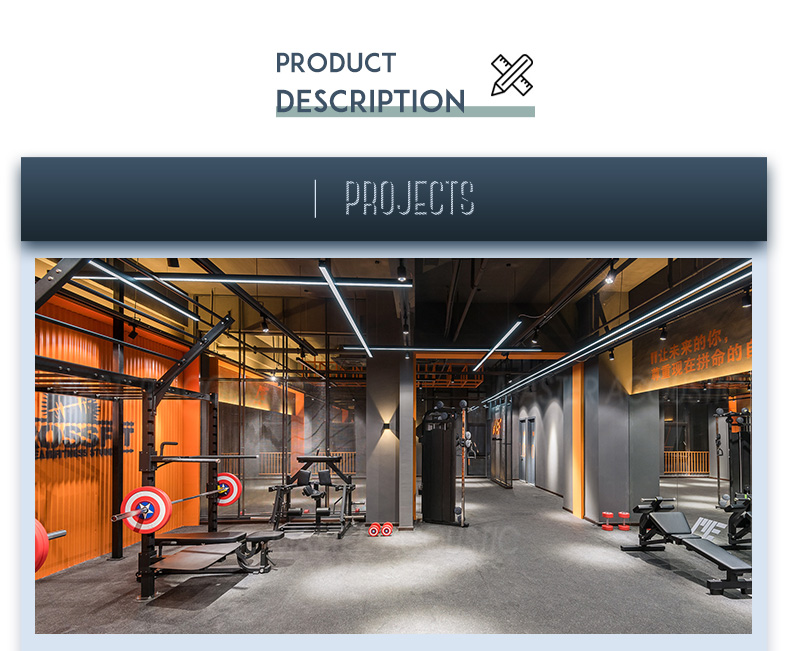

MLV can be used in residential, commercial, and industrial settings. Common applications include soundproofing walls, ceilings, floors, HVAC ducts, and pipes.

● Soundproofing Performance

MLV is especially effective at blocking airborne noise, such as voices, music, or traffic noise. It can also help with impact noise reduction to some extent.

● Thermal Insulation

In addition to sound insulation, MLV can provide some degree of thermal insulation, which can be beneficial in certain applications.

When using MLV for sound insulation, it's important to ensure proper installation and sealing of seams and edges to maximize its effectiveness. Additionally, MLV is often used in conjunction with other soundproofing materials, such as acoustic panels or fiberglass insulation, for comprehensive noise reduction.

Keep in mind that while MLV is an effective soundproofing material, it may not eliminate all noise completely. The level of noise reduction achieved depends on various factors, including the thickness of the MLV, the construction of the surrounding walls or surfaces, and the frequency of the sound being blocked.

Product parameters

Name: Ceiling space absorber

Finishes: fiberglass cloth, acoustic cloth

Structure: Acoustic cloth→Aluminum alloy frame→Glass fiber cotton board

Style: full-covered cloth, half-covered cloth, external frame

Color: hundreds of colors

Width: 600mm, 1200mm

Length: 1200mm, 2400mm

Thickness: 50mm, 100mm

Size: Allowable tolerance, width±2mm, length±2mm, height±0.5mm

A. Acoustic performance

The panel space sound absorber is a suspended sound-absorbing structure. It is not a sound-absorbing structure combined with rigid walls such as walls, but a self-made sound-absorbing system, used in large spaces to reduce indoor noise or improve indoor sound quality conditions, and is suitable for hanging on ceilings to increase space utilization.

B. The number of suspensions

The number of suspended sound absorbers in the space should be calculated and determined according to the sound absorption characteristics of the sound absorbers and the increased sound absorption required to reduce indoor noise (or control the reverberation time). When the plate-shaped space sound absorber is used in the design, if the total area of the sound absorber is equivalent to 30-40% of the roof area of the building, the sound absorption efficiency of the plate-shaped space sound absorber can reach the best value.

C. Application space

Applicable places: gymnasiums, basketball courts, school auditoriums, meeting rooms, lecture halls, museums, indoor entertainment venues and other spaces that need noise reduction.

D.Installation method

Space sound absorbers are mostly hung on the top of the building space, and most of them are hung off the top. The plate-shaped space sound absorber can be suspended horizontally or vertically, and can also be suspended horizontally and vertically. In the case of the same total area, the noise reduction effect is basically the same.

1. Are you a trading company or a factory?

Our company was established in Guangzhou city, with the factory in Foshan. We are a manufacturer engaged in acoustic products for more than 10 years. Welcome to visit our factory.

2. How can you guarantee the quality?

We are strict on every step of production to ensure the best quality. We provide full-scale quality management system and passed ISO9001 quality assurance system.

3. Can you offer sample?

Yes, we can offer standard samples for free, and customization is available.

4. Do you accept customization?

Yes, we can support our clients with OEM, so that it can be easier to open the local market and build a long-term partnership between us.

5. How long is the lead time?

Normally 10-25 days upon receiving the deposit, base on the quantity 1,500 SQM

6. Can you assist for installation?

Yes, we can arrange to assist in installation if needed.

7. Do you have CE certificate?

Yes, we have. We have shipped many goods to European countries.

8. What are the factors of influencing the NRC?

Perforation rate, gap between the wall and panel, the density and thickness of the glass wool, etc. All these factors will effect NRC.

9. How about the capacity of your factory?

We can produce 500,000 sqm acoustic materials per year.

10. How to pay?

You can pay by western union or T/T. Cash will be ok if we do business face to face .

More questions or details about our products or company, please feel free to contact us.