- Home

- Acoustic Materials

- Project

- Information

- Service

- About Master Acoustic

- Contact Us

-

Master acoustic wood wool panels, combined with inorganic hard cement binders, are manufactured under the conditions of high temperature and high pressure using a continuous operation process.

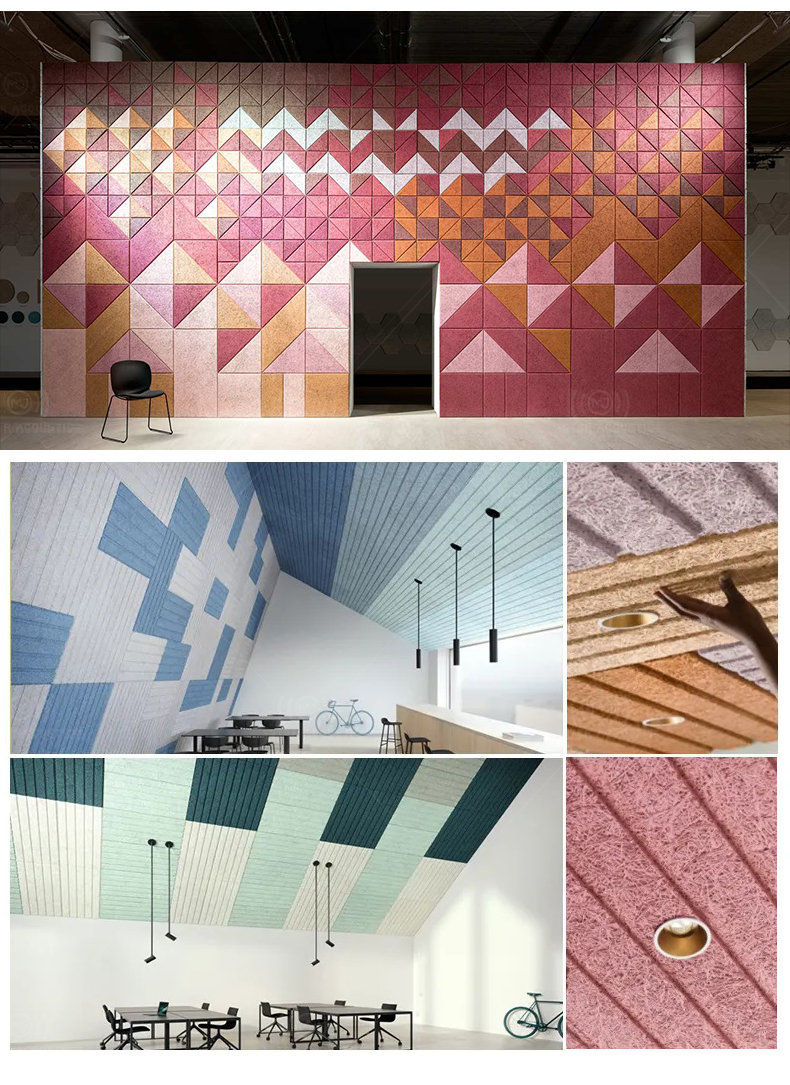

The wood wool acoustic panels have a unique appearance and good sound absorption unique surface silky texture gives people a primitive and rough feeling, which satisfies the modern people's idea of returning to nature. The surface can be painted and painted.

INQUIRYWood fiber acoustic board is a decoration material, using flame retardant resin border placed fireproof Class A specially designed non-combustible sound-absorbing cotton, made of outsourcing fireproof treatment flame-retardant B level acoustic fabric or leather.

Wood wool acoustic panel sound absorption spectrum is high, which has fairly good results for low, medium, and high-frequency noises, and good fire-proof, has no dust pollution, has strong decorative, and is simple to use.

● Stable product quality, zero complaints

● Standard products, available in stock

● The product has the function of sound absorption and noise reduction and is highly decorative

● Wide range of applications, suitable for housing commercial decoration

● Use of website sales and distributor channel sales

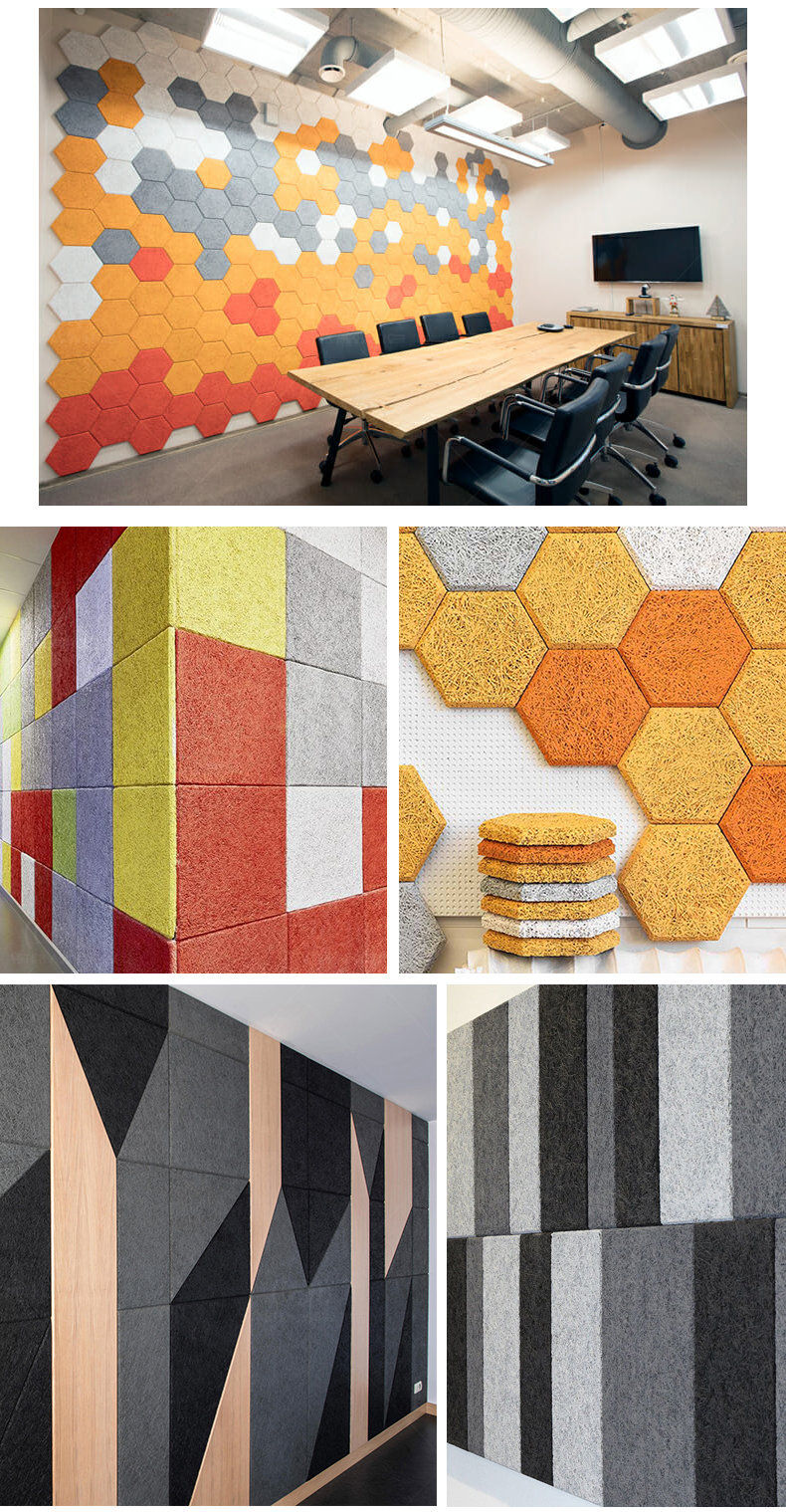

Wood wool acoustic panels are characterized by being available in a variety of colors and patterns to choose from. The finish color can be adjusted according to the requirements of the acoustic renovation or investors; There are many specification levels available for investors to choose from, which you can simply note when installing.

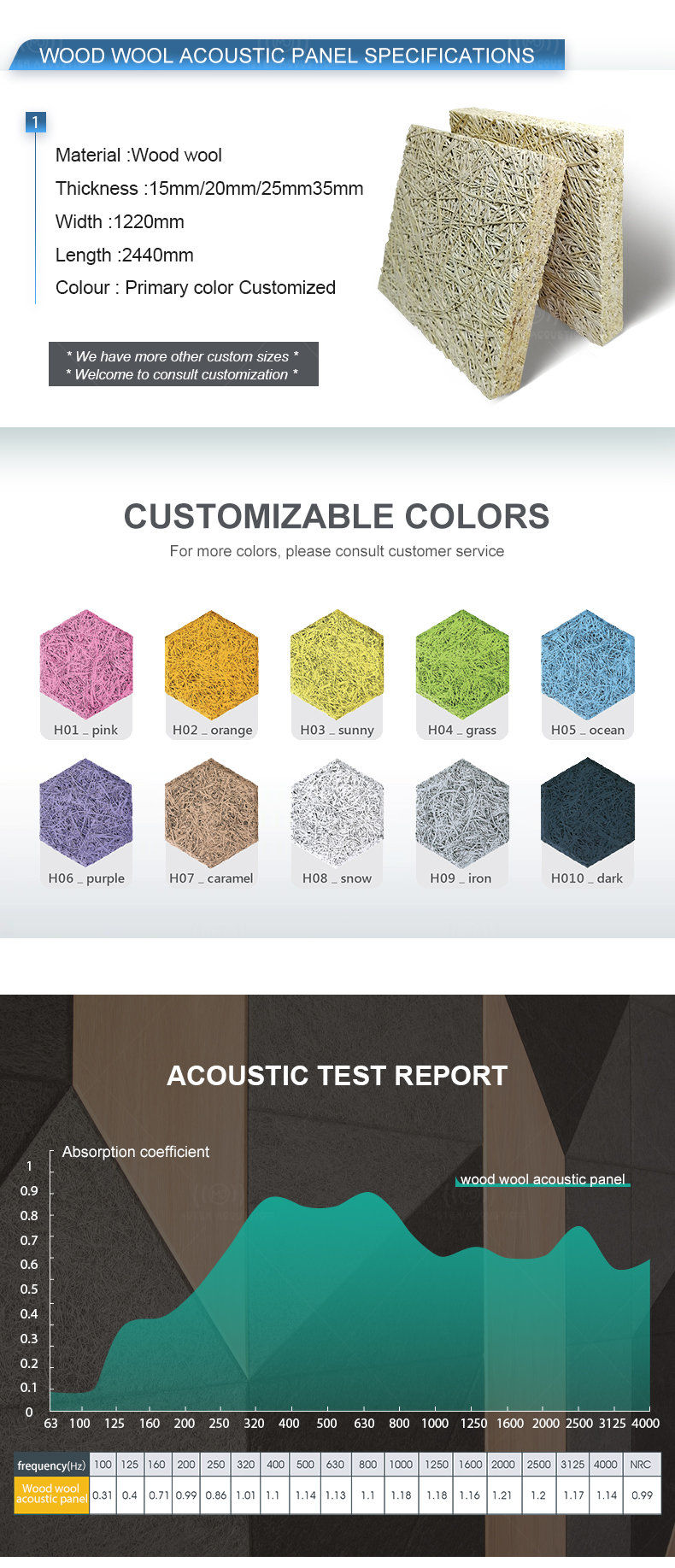

Product parameters

Product name: wood wool sound-absorbing board

Substrate: Wood wool

Color: Painting by Pantone/ral color

Density: 580kg/m³/customized

Width: 1220mm

Length: 2440mm

Thickness: 15mm, 20mm, 25mm,35mm

A.Features:

1) Strong structure-strong structure, full of elasticity, impact resistance, can withstand repeated impacts of basketball, football and volleyball without cracks or breakage when used in gymnasiums.

2) Simple installation—easy to cut, simple installation method, just general woodworking tools.

3) Antibacterial and moisture-proof — 25mm panels can be used under 85% humidity conditions, including open air and swimming pools, except for places that directly contact water.

4) Energy-saving and heat preservation, long lifespan—Because it is mainly made of wood, it has strong heat insulation performance. Economical and durable, long service life, can be customized size according to requirements.

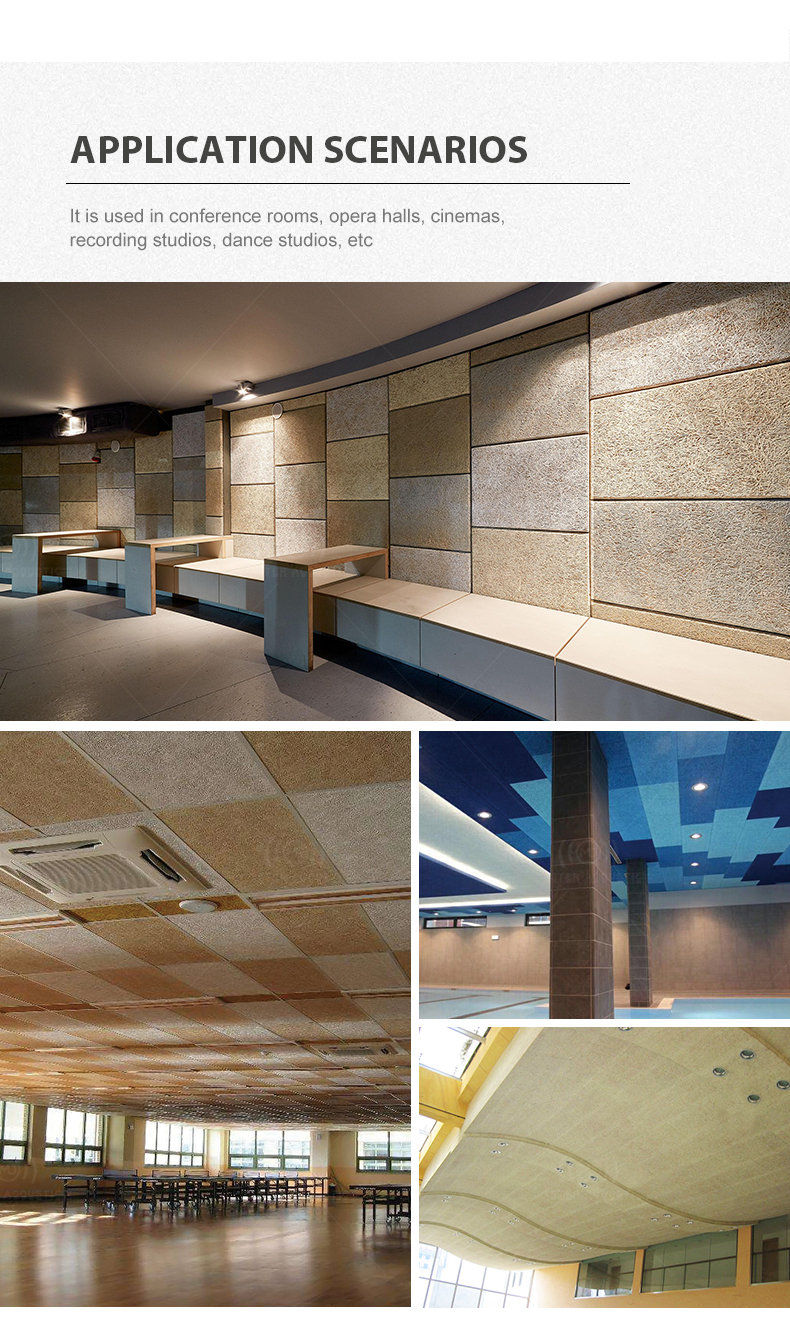

B.Application space

Applicable places: gymnasiums, swimming pools, cinemas, conference rooms, lecture halls, multi-function halls, schools, museums, libraries, hospitals, tunnels, bars, entertainment venues and other spaces that need sound absorption.

C.Wall mounting method

1)Advance the base surface, keep the construction surface dry and clean, and it is strictly forbidden to construct on the wet base surface. Because it is damp or unclean in the closed condition, it is very easy to produce some unhealthy bacteria, which can lead to mildew on the wall.

2)In the case of a keel, ordinary stainless steel nails are obliquely nailed from the side of the wood wool sound-absorbing board with a thickness of 20mm, and the keel is generally a sharp gun nail.

3)Light steel keel, when the high-rise building or the fire protection level is higher, the construction of wooden keel may not be allowed, generally a small piece of wood washer is fixed on the light steel keel by explosive screws, and then the wood wire is used. The sound-absorbing board can be fixed on the veneer.

4) If there is no keel on the wall, use glass glue or other glue to directly bond the wood wool sound-absorbing board. If possible, you can fix it with sharp gun nails at the corners.

1. Are you a trading company or a factory?

Our company was established in Guangzhou city, with the factory in Foshan. We are a manufacturer engaged in acoustic products for more than 10 years. Welcome to visit our factory.

2. How can you guarantee the quality?

We are strict on every step of production to ensure the best quality. We provide full-scale quality management system and passed ISO9001 quality assurance system.

3. Can you offer sample?

Yes, we can offer standard samples for free, and customization is available.

4. Do you accept customization?

Yes, we can support our clients with OEM, so that it can be easier to open the local market and build a long-term partnership between us.

5. How long is the lead time?

Normally 10-25 days upon receiving the deposit, base on the quantity 1,500 SQM

6. Can you assist for installation?

Yes, we can arrange to assist in installation if needed.

7. Do you have CE certificate?

Yes, we have. We have shipped many goods to European countries.

8. What are the factors of influencing the NRC?

Perforation rate, gap between the wall and panel, the density and thickness of the glass wool, etc. All these factors will effect NRC.

9. How about the capacity of your factory?

We can produce 500,000 sqm acoustic materials per year.

10. How to pay?

You can pay by western union or T/T. Cash will be ok if we do business face to face .

More questions or details about our products or company, please feel free to contact us.